With the continuous development of industrial technology, Ultra-high Speed Integrated Bearing has become an innovative technology in the field of mechanical engineering. This kind of bearing can not only cope with extremely high speed requirements, but also has the characteristics of integrated design, bringing new solutions to high-speed rotating equipment in various industries. This article will deeply explore the innovations of ultra-high-speed integrated bearings and their application prospects in various fields.

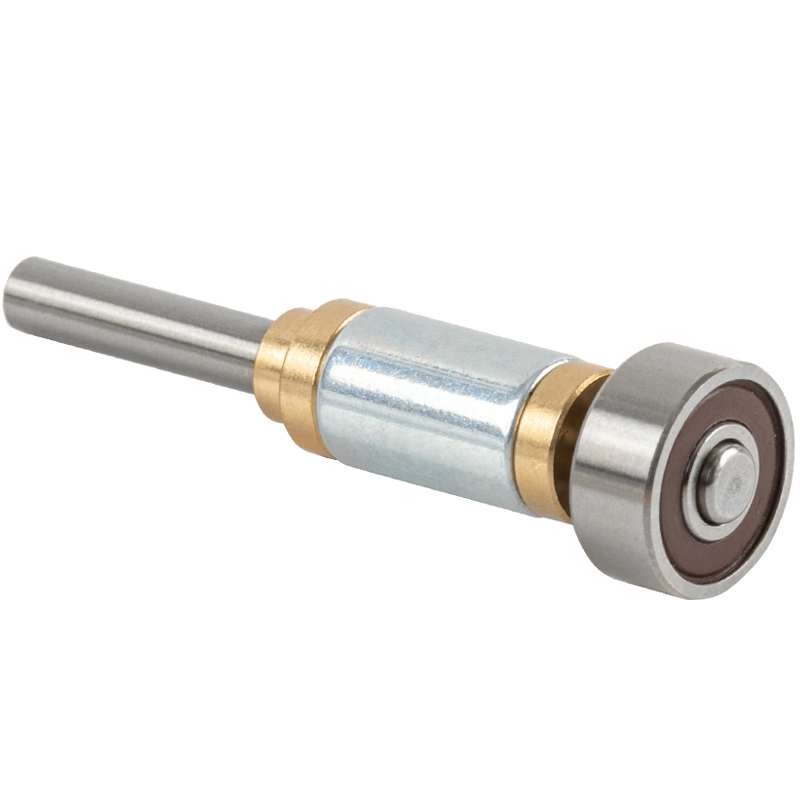

Advantages of integrated design:

Ultra-high-speed integrated bearings reduce assembly complexity and improve overall stability by integrating multiple components of traditional bearings into a single structure. This integrated design not only reduces the burden on the equipment, but also reduces the difficulty of maintenance and upkeep, providing convenience for long-term operation of high-speed rotating equipment.

Adaptability to ultra-high speed:

Traditional bearings are susceptible to vibration and friction at extremely high speeds, while ultra-high-speed integrated bearings can maintain good performance in ultra-high-speed environments by using advanced materials and precision manufacturing processes. This makes the bearing ideal for high-speed rotating equipment in wind power, aerospace and other fields.

Reduce energy consumption:

Ultra-high-speed integrated bearings reduce friction loss and energy consumption through optimized design. In fields such as the power industry and automobile manufacturing, this means more efficient energy use, helping to promote sustainable development.

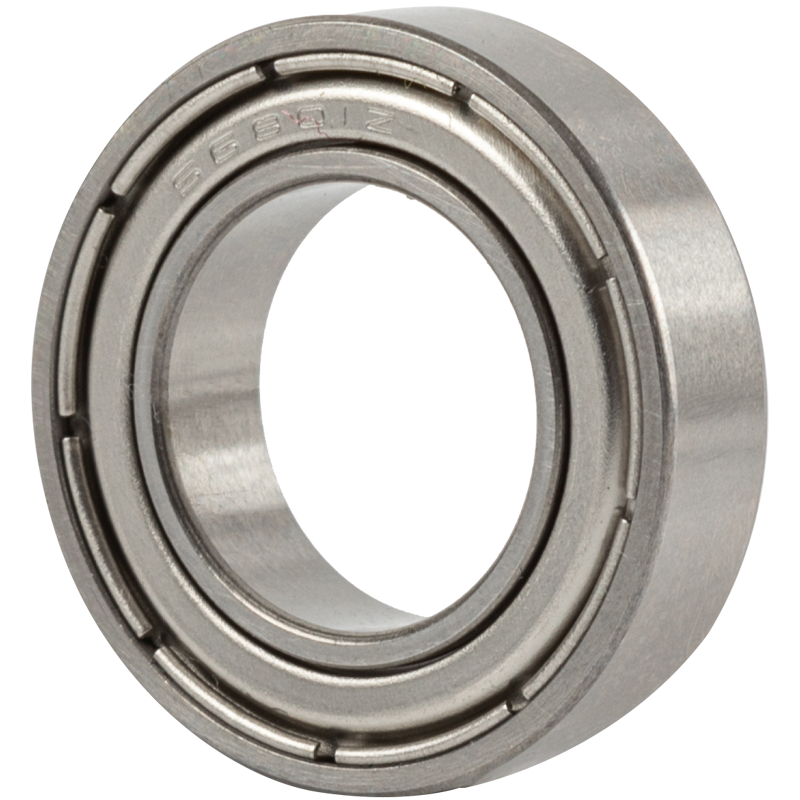

Advanced materials and lubrication technology:

In order to adapt to the ultra-high-speed environment, the bearing uses advanced high-temperature-resistant and wear-resistant materials, combined with advanced lubrication technology to ensure that it can still maintain good lubrication conditions under high-speed operation and extend its service life.

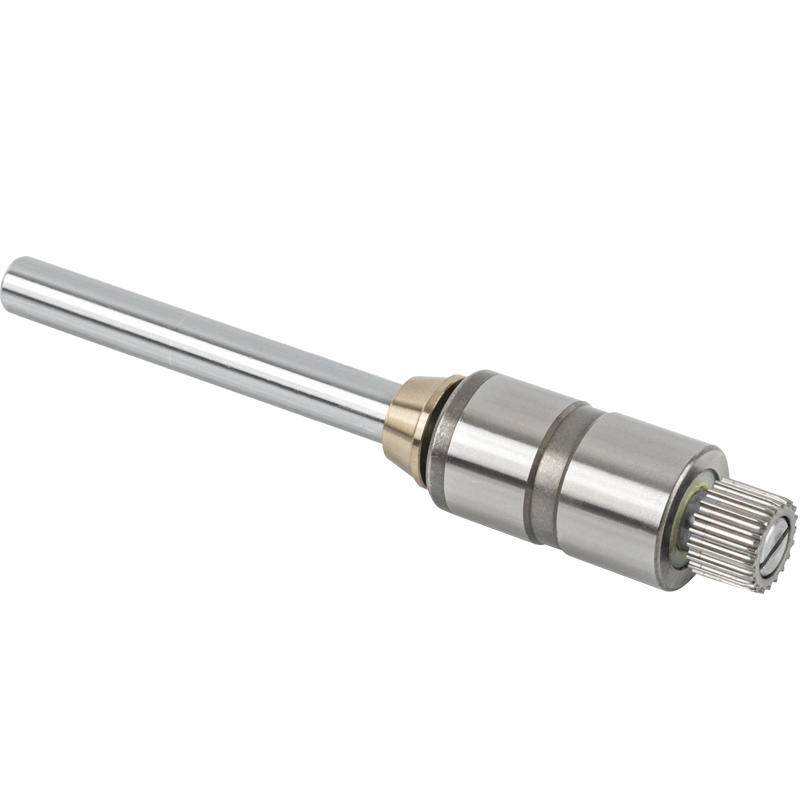

Aerospace and high-speed train applications:

Ultra-high-speed integrated bearings have broad application prospects in the fields of aerospace and high-speed trains. Its lightweight design and excellent high-speed performance enable it to meet the strict requirements for high-speed and stable operation of aircraft engines, high-speed train axles and other equipment, improving the performance and safety of transportation.

Developments in data center and hard disk technology:

Ultra-high-speed integrated bearings also play an important role in data centers and hard drive technology. Its high-speed and high-precision characteristics enable it to support the high-speed rotation of storage devices such as hard disks, improving data storage and transmission efficiency.

Vibration control and noise reduction:

Integrated design and advanced manufacturing processes help reduce vibration and noise. In applications with strict requirements on vibration and noise, such as medical equipment and precision instruments, ultra-high-speed integrated bearings can provide more stable and quiet operation.

The innovative design and excellent performance of ultra-high-speed integrated bearings give it broad application prospects in various fields. Its adaptability to high-speed rotating equipment, improvement of energy efficiency, and innovative applications in aviation, transportation, data centers and other fields will promote the continuous progress of industrial technology and provide more efficient and reliable solutions for all walks of life.

English

English 日本語

日本語 Tiếng Việt

Tiếng Việt