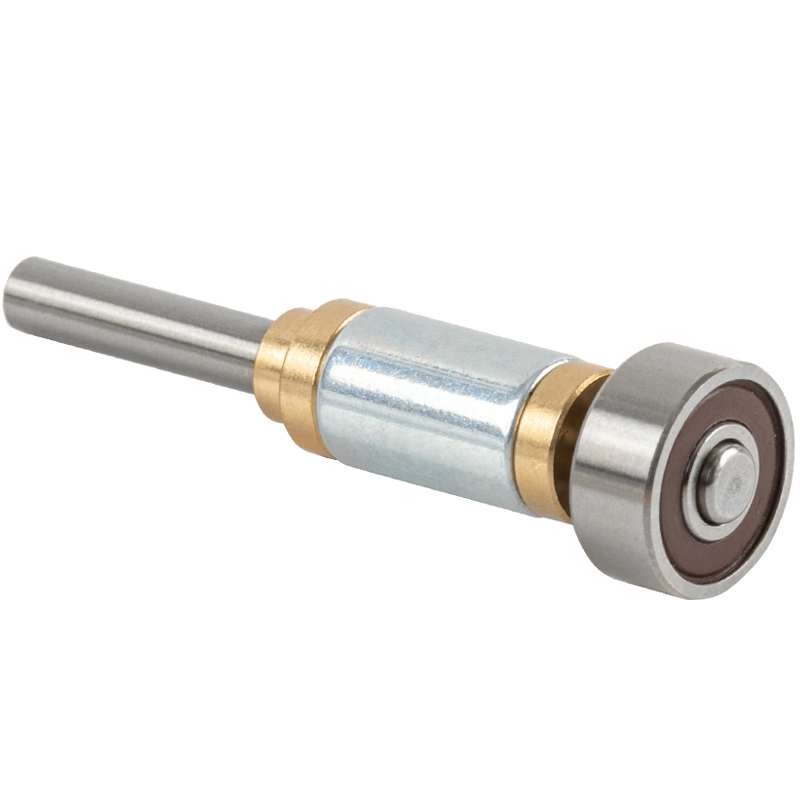

1. Inner diameter (ID) and outer diameter (OD):

The ID and OD define the size of the bearing. For small and medium-sized deep groove ball bearings, the ID can usually be 0.6mm, while the OD may be less than 9mm in the metric series and less than 9.525mm in the imperial series. These size parameters determine the size of the shaft and bearing seat on which the bearing can be installed.

When selecting, it is necessary to determine the appropriate ID and OD of the bearing based on the size of the shaft and the bearing seat to ensure that the bearing can be properly installed and operate stably.

2. Load capacity:

Load capacity is a key parameter in bearing selection, which determines the maximum force that the bearing can withstand. Depending on the application, the bearing may need to withstand radial loads, axial loads, or a combination of both.

When selecting, it is necessary to select a bearing with sufficient load capacity based on the operating conditions of the equipment and the expected load size.

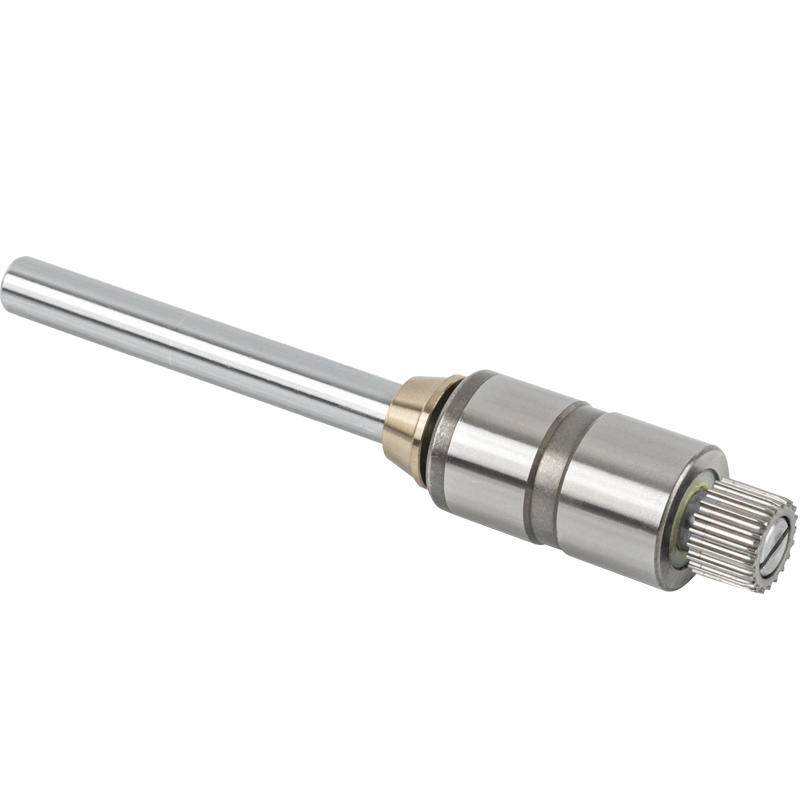

3. Maximum speed:

The maximum speed is the maximum speed at which the bearing can operate safely. Deep groove ball bearings are particularly suitable for high-speed applications due to their low friction resistance and high speed.

When selecting, it is necessary to select a bearing with a sufficient maximum speed according to the working speed of the equipment to ensure the stability and safety of the bearing when running at high speed.

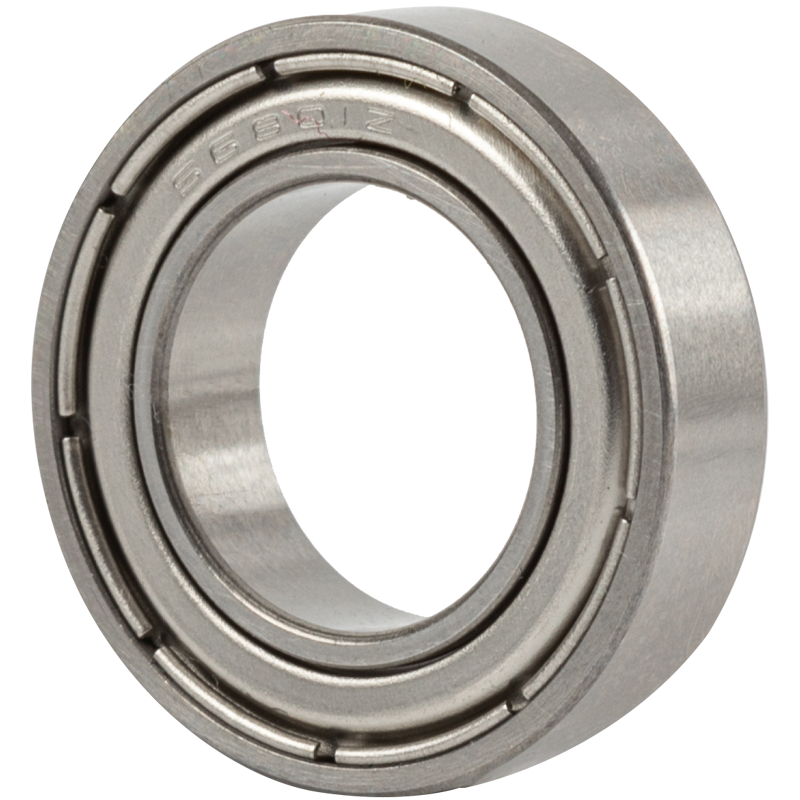

4. Structural type:

Deep groove ball bearings have a variety of structural types, such as with dust cover, with rubber seal, with retaining groove, etc. The selection of these structural types depends on the needs of the application.

For example, in situations where dust needs to be prevented from entering or grease spills, bearings with dust covers or rubber seals can be selected; in situations where axial displacement needs to be limited, bearings with retaining grooves can be selected.

5. Accuracy grade:

The accuracy grade of the bearing determines its rotational accuracy and friction torque. For equipment that requires high-precision operation, high-precision grade bearings should be selected.

When selecting, it is necessary to select bearings with appropriate accuracy grades according to the accuracy requirements of the equipment.

6. Material selection:

The material of the bearing is also one of the factors that need to be considered when selecting. Different materials have different mechanical properties, wear resistance and corrosion resistance.

When selecting, it is necessary to select bearings with appropriate materials according to the working environment and requirements of the equipment.

English

English 日本語

日本語 Tiếng Việt

Tiếng Việt