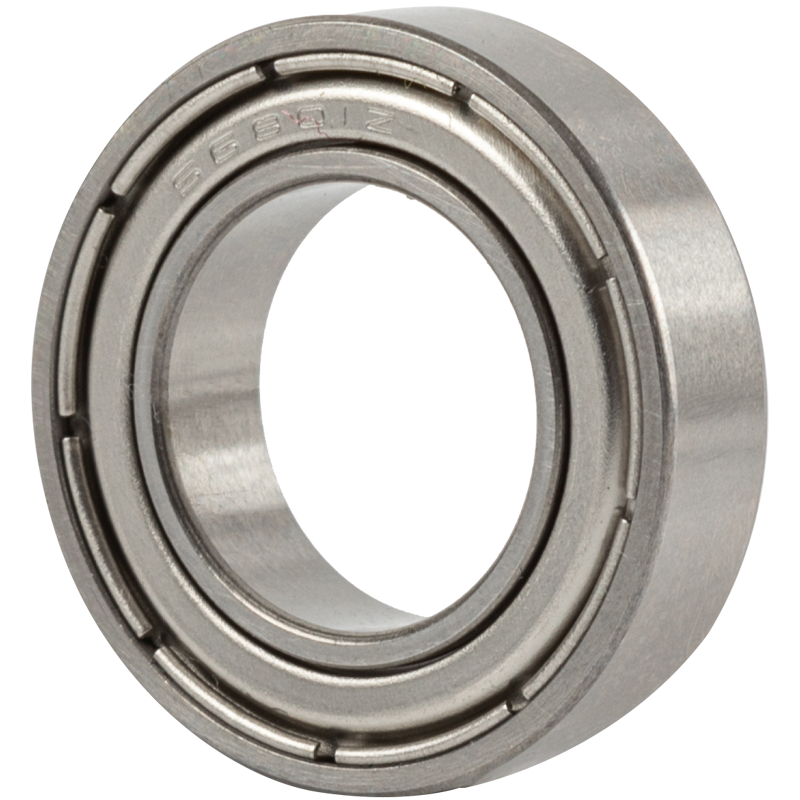

Deep groove ball bearings are one of the most widely used types of ball bearings, known for their versatility, efficiency, and ability to handle both radial and axial loads. These bearings consist of an inner and outer ring, a set of balls, and a cage that keeps the balls evenly spaced. They can be found in a vast range of industrial machinery and consumer products due to their simple design, high load capacity, and ability to operate at high speeds with minimal friction. Below, we explore the most common applications of deep groove ball bearings in both industrial machinery and everyday consumer products.

1. Electric Motors

Deep groove ball bearings are extensively used in electric motors, particularly in applications where high speed and low friction are essential. These bearings help reduce energy consumption and ensure smooth operation of motors. In small electric motors, such as those found in appliances, power tools, and office equipment, deep groove ball bearings are commonly employed to handle radial loads and support axial thrust. The bearings also contribute to reducing noise and vibration, improving overall performance.

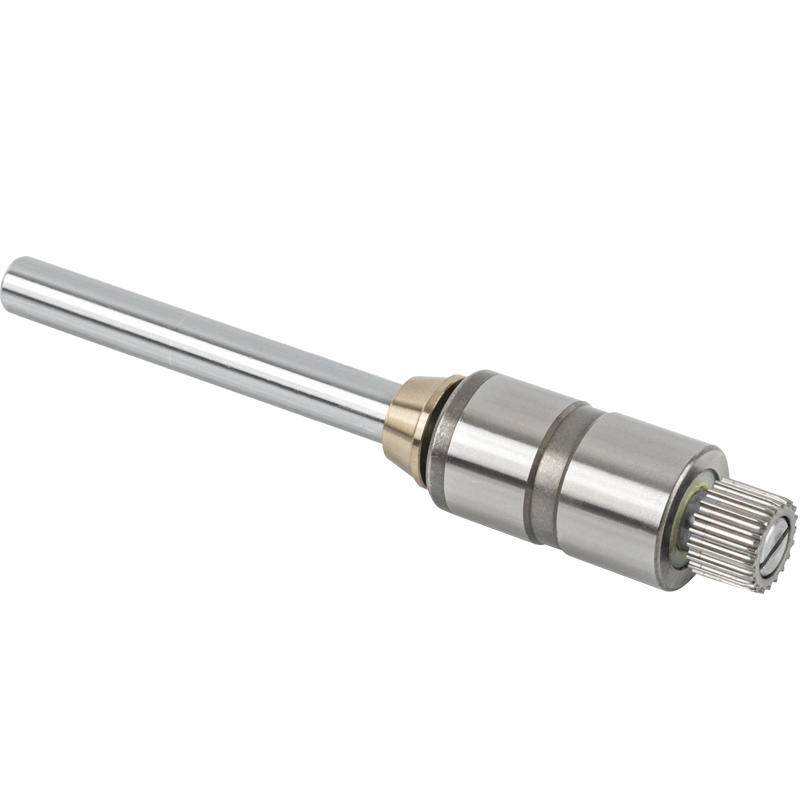

2. Automotive Industry

In the automotive sector, deep groove ball bearings play a crucial role in ensuring the smooth operation of various components. They are used in engine systems, wheel hubs, transmission assemblies, and suspension systems. In wheel hubs, deep groove ball bearings support both radial and axial loads, helping the wheels rotate smoothly under the vehicle's weight. Similarly, in the transmission system, these bearings are used to reduce friction between rotating shafts and other moving parts, contributing to better performance and longer lifespan of the vehicle.

Moreover, deep groove ball bearings are used in electric vehicle (EV) motors, power steering systems, and air conditioning units in vehicles, showcasing their versatility in modern automotive applications.

3. Pumps and Compressors

Deep groove ball bearings are commonly used in pumps and compressors, which are critical components in industries such as oil and gas, water treatment, and HVAC (Heating, Ventilation, and Air Conditioning). In these applications, the bearings help support the rotating shafts, reducing friction and wear. The smooth operation enabled by deep groove ball bearings ensures that pumps and compressors can operate efficiently, even under varying loads and high-speed conditions. Their durability helps minimize maintenance requirements, making them ideal for industrial applications where uptime is crucial.

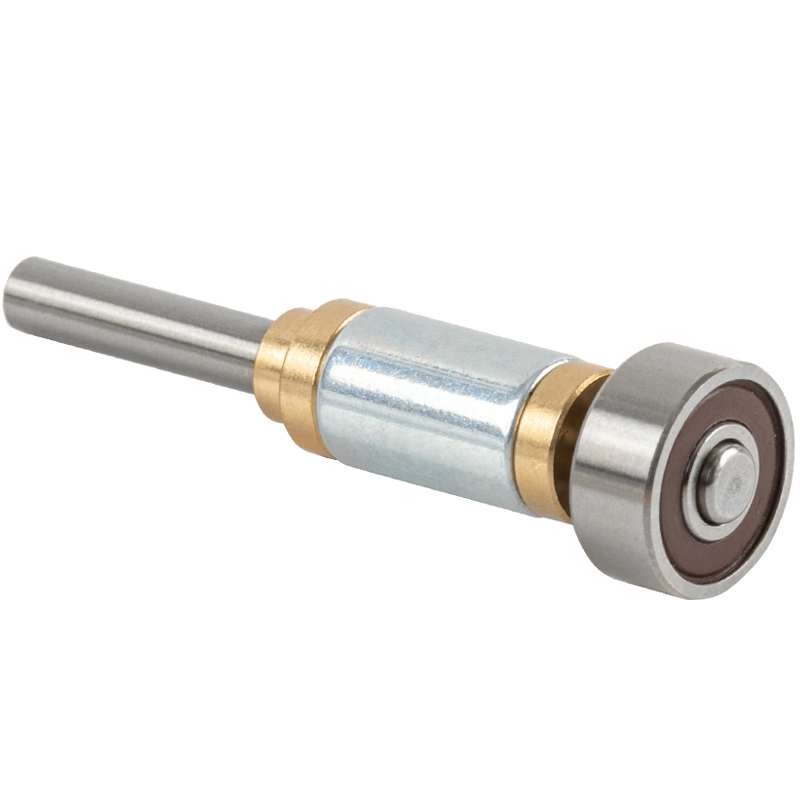

4. Machine Tools

In the world of industrial machinery, machine tools such as CNC (Computer Numerical Control) machines, lathes, mills, and grinders make extensive use of deep groove ball bearings. These bearings are employed to support high-speed spindles, reducing friction and maintaining precision. In machine tools, deep groove ball bearings provide the stability needed for consistent performance, ensuring that tools operate smoothly even during complex machining tasks. Their ability to handle both radial and axial loads is particularly beneficial in maintaining the accuracy and stability of machine components during operation.

5. Agricultural Machinery

Agricultural equipment, including tractors, harvesters, and plows, often incorporates deep groove ball bearings to reduce friction and ensure the reliability of moving parts. These bearings are used in the wheels, axles, and gearboxes of agricultural machinery. The ability to handle heavy loads and operate efficiently in harsh conditions makes deep groove ball bearings essential in keeping agricultural machinery functioning smoothly. They also help extend the service life of these machines by reducing wear and tear on components that experience constant movement and pressure.

6. HVAC Systems

In HVAC systems, deep groove ball bearings are used in fans, blowers, and air conditioning compressors. These bearings are crucial for reducing friction in rotating parts, enabling the efficient movement of air and ensuring consistent cooling or heating. In air conditioning units, deep groove ball bearings are often employed to support the compressor shaft, minimizing friction and ensuring reliable performance over time. Their ability to handle both radial and axial loads makes them ideal for use in high-performance HVAC systems.

7. Consumer Electronics

Deep groove ball bearings can also be found in various consumer electronics, particularly those involving motors or moving parts. Examples include personal fans, vacuum cleaners, and electric shavers. In these products, the bearings help reduce friction, improve the efficiency of the motors, and ensure that the devices operate quietly and smoothly. In electric fans, for example, the bearings support the fan blades, enabling them to rotate at high speeds without excessive wear. This reduces the amount of maintenance required and enhances the overall user experience.

8. Bicycles

In the bicycle industry, deep groove ball bearings are used in various components such as wheel hubs, bottom brackets, and headsets. In wheel hubs, they enable smooth rotation of the wheels by reducing friction and supporting both radial and axial loads. In the bottom bracket and headset, deep groove ball bearings allow for smooth pedal and steering motion, contributing to the overall performance and comfort of the ride. Their reliability and durability make them ideal for ensuring that bicycles continue to perform well even under heavy use.

9. Household Appliances

Many household appliances such as washing machines, dryers, and dishwashers also use deep groove ball bearings. In washing machines, for example, deep groove ball bearings are typically used in the drum assembly to allow for smooth rotation during the washing and spinning cycles. These bearings help reduce noise and vibration, ensuring that the machine operates quietly and efficiently. In dishwashers, they are used in the rotating spray arms, enabling even water distribution for cleaning dishes. Their ability to operate under varying loads and conditions makes them a perfect fit for such home appliances.

10. Office Equipment

Deep groove ball bearings are found in various office equipment such as printers, copiers, and fax machines. These bearings are essential for the smooth functioning of the moving parts within these machines, such as rollers, gears, and paper feeding mechanisms. In printers, deep groove ball bearings support the movement of the paper feed system and printhead, ensuring high-speed operation and minimizing mechanical wear. Their low friction and ability to handle both radial and axial loads make them essential for ensuring reliability and efficiency in office equipment.

English

English 日本語

日本語 Tiếng Việt

Tiếng Việt