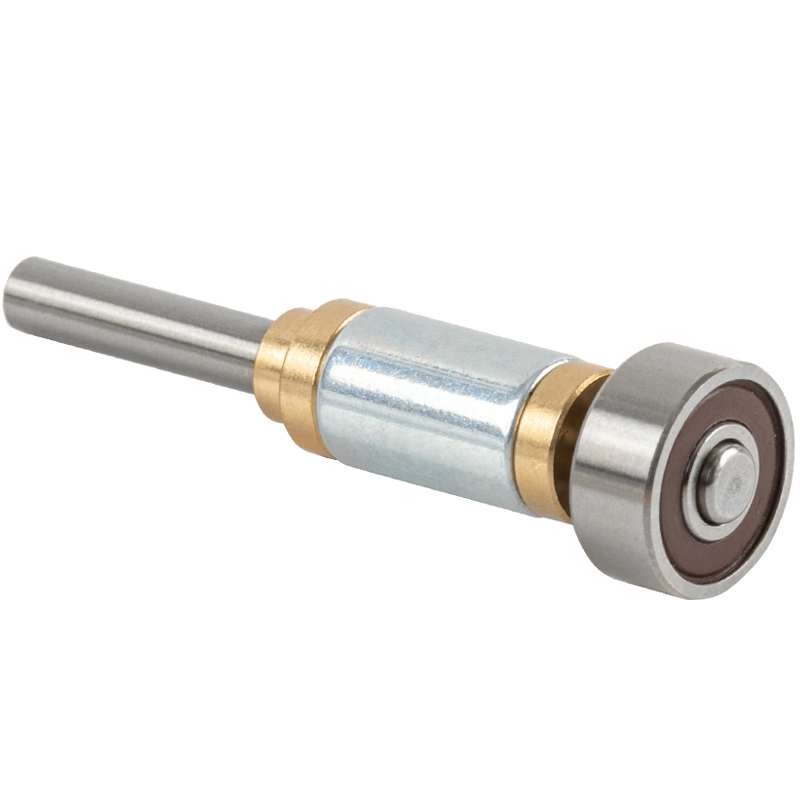

In automotive air conditioning (AC) systems, the compressor is one of the most crucial components, and its performance and stability are largely dependent on the AC compressor bearing. As an essential part of the compressor, the primary function of the AC compressor bearing is to support and ensure the proper operation of the moving components, reduce friction, and maintain stable rotation, thereby improving the overall efficiency and lifespan of the compressor.

1. Main Functions of the auto AC compressor bearing

The AC compressor bearing serves several critical roles, including:

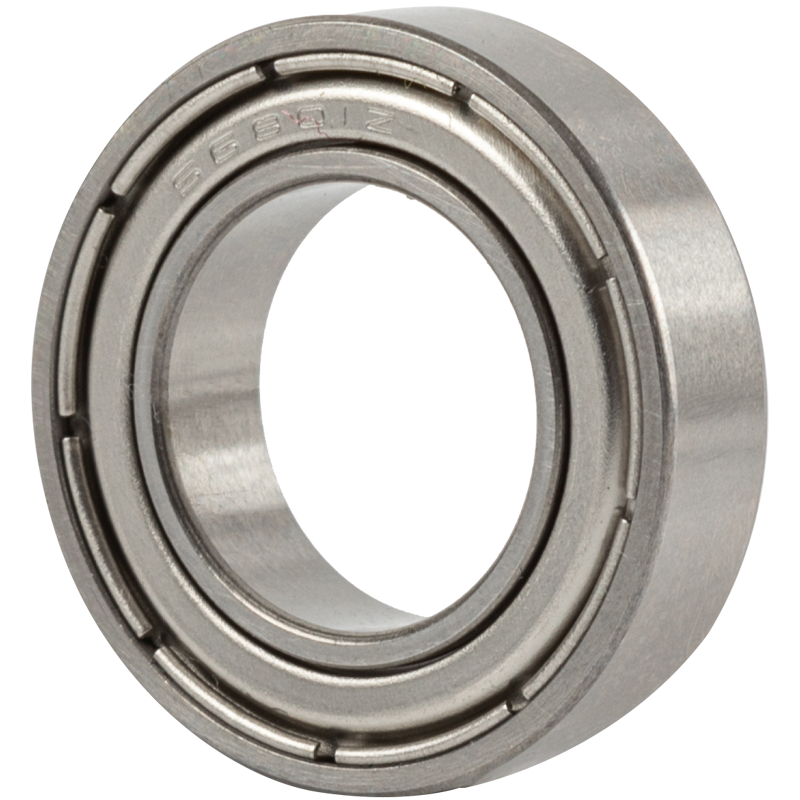

Reducing Friction: The bearing provides a smooth rolling surface, minimizing friction between the shaft and compressor housing, which helps reduce energy loss and wear on the bearing.

Bearing Load: The compressor operates under significant load, particularly in high-pressure and high-temperature conditions. The bearing helps evenly distribute this load, preventing excessive wear or damage.

Maintaining Rotational Stability: The bearing ensures that the rotating components of the compressor maintain balance and operate at a consistent speed and force, preventing irregular vibrations and unnecessary noise.

Therefore, the AC compressor bearing is essential for the normal operation of the compressor, and any failure in the bearing will directly impact compressor efficiency, potentially leading to AC system failure.

2. How the AC Compressor Bearing Affects Compressor Efficiency

The performance of the AC compressor bearing has a direct impact on the overall operation of the compressor. This impact is seen in several ways:

2.1 Reducing Energy Loss

When the bearing experiences excessive friction, the compressor has to work harder to overcome this resistance, leading to increased energy consumption and reduced overall efficiency. A high-quality, low-friction bearing minimizes energy loss, enabling the compressor to operate more efficiently. This translates into better cooling performance and enhanced energy utilization across the AC system.

2.2 Improving Compressor Stability

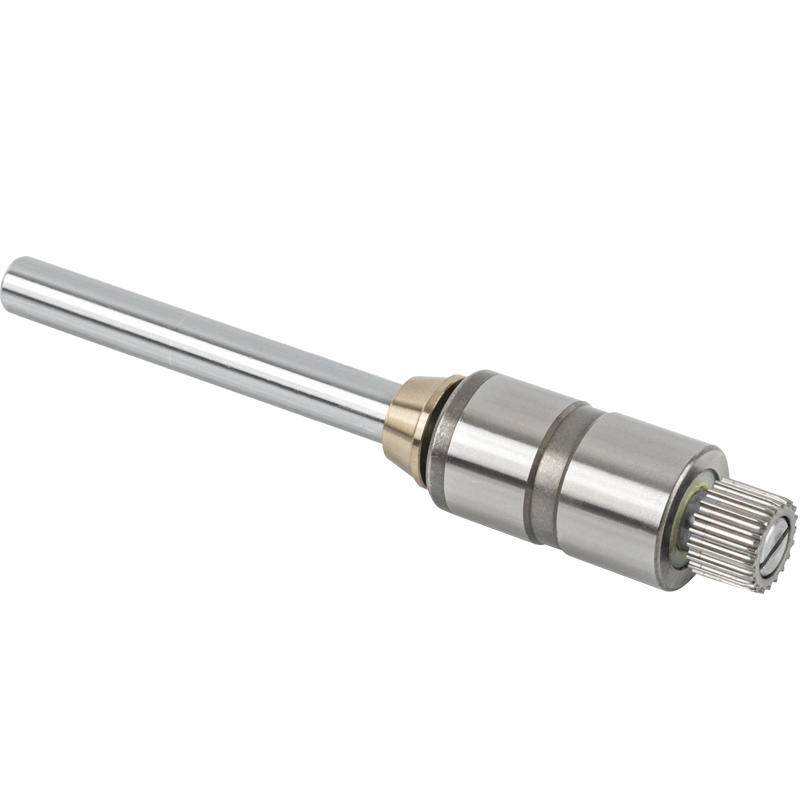

The AC compressor often runs at high speeds, and the bearing's performance is crucial for maintaining stable operation. If the bearing is of poor quality or becomes worn, the compressor may experience vibrations or irregular rotation, affecting the cooling efficiency and putting extra load on other components. A well-performing bearing helps ensure that the compressor runs smoothly and consistently, even under high pressure.

2.3 Extending Compressor Lifespan

A good bearing design reduces wear on the compressor’s moving components, prolonging the overall lifespan of the AC system. Premature bearing wear or failure not only impacts compressor efficiency but also accelerates wear on other critical parts (such as the compressor shaft or piston), which may lead to more significant damage and a shorter service life for the system. Regular inspection and timely replacement of compressor bearings are essential to extending the AC system’s longevity.

2.4 Reducing Noise and Vibration

The AC compressor bearing also plays an important role in reducing noise and vibration during compressor operation. As bearings wear out or lack proper lubrication, the compressor may produce abnormal sounds and vibrations, which can affect user comfort and contribute to further mechanical damage. A high-quality bearing helps mitigate these issues, improving the overall comfort and stability of the AC system.

2.5 Enhancing Cooling Efficiency

The efficiency of the compressor directly influences the overall cooling capacity of the AC system. When the bearing is not performing well, the compressor’s efficiency decreases, resulting in poor cooling performance, especially under high load or extreme temperature conditions. A high-quality bearing ensures optimal performance of the compressor under various conditions, enhancing the overall cooling efficiency of the AC system.

English

English 日本語

日本語 Tiếng Việt

Tiếng Việt